MZ ELECTRONIC

PRODUCTS

MZ ELECTRONIC ·

MZ ELECTRONIC

ABOUT US

Wuhan MZ Electronic Co., Ltd

Wuhan MZ Electronic is a leading manufacturer specializing in the production of high-quality cable management solutions.With a focus on innovation and quality, we have established ourselves as a trusted supplier in the industry.

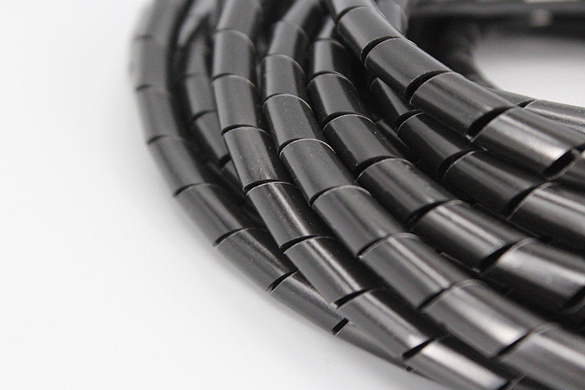

Our products range focus on the cable management, ranging of nylon cable ties, hook and loop cable ties, stainless steel cable ties, cable clips, cable glands, cable tie mounts, cable holders, wire connectors, spiral wrapping band and other cable/wiring accessories.

READ MORE →MZ ELECTRONIC

HOT PRODUCT

MZ ELECTRONIC

SUPPORT

MZ ELECTRONIC

NEWS CENTER

Insect-proof plastic cable ties

Plastic cable ties, essential for organizing cables and securing equipment, face unique challenges in environments prone to insect activity. Standard ties may degrade when exposed to bites, secretions, or nesting behaviors of pests, leading to premature failure. Insect-resistant plastic cable ties address these issues through specialized material formulations, offering enhanced durability and reliability. Below, we explore the key material properties that make these ties suitable for pest-prone settings.

09

2025-10

Advantages of dust-proof plastic cable ties

Plastic cable ties, commonly known as zip ties, are indispensable tools across industries due to their versatility and cost-effectiveness. When designed with dust-resistant properties, these ties gain additional benefits that enhance their performance in environments prone to particulate contamination.

09

2025-10

Application scenarios of waterproof plastic cable ties

Waterproof plastic zip ties, engineered with materials like UV-stabilized nylon or polypropylene, are designed to resist moisture, chemicals, and environmental degradation. Their durability and adaptability make them indispensable across industries and daily life. Below are key applications where these ties excel.

08

2025-10

Surface treatment of anti-slip plastic cable ties

Plastic zip ties are essential for securing items, but their smooth surfaces can sometimes lead to slippage, especially under tension or in wet conditions. This compromises both functionality and safety, particularly in applications like construction, automotive repairs, or outdoor installations. By applying specialized surface treatments, manufacturers can significantly improve the grip and durability of zip ties, ensuring they stay firmly in place even in challenging environments.

08

2025-10

Plastic cable tie design with reduced wear

Plastic zip ties are widely used for securing items, but frequent movement, vibration, or exposure to abrasive surfaces can lead to premature wear, reducing their lifespan and reliability. By incorporating thoughtful design elements, manufacturers can create zip ties that resist wear more effectively, ensuring consistent performance even in demanding environments.

08

2025-10